Me pēhea te whakapai ake i te kounga o te mata o te HIPS

Me pēhea te whakapai ake i te kounga o te mata o te HIPS,

NGĀ HŪPA, whakapai ake i te kounga o te mata o te HIPS, kaihanga masterbatch silicone, Ka whakapai ake te kounga o te mata i te masterbatch silicone SILIKE,

Whakaahuatanga

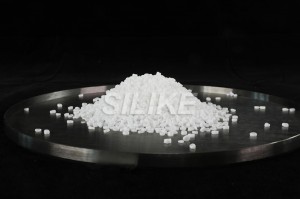

Ko te Silicone Masterbatch (Siloxane Masterbatch) LYSI-410 he ranunga i hangaia ki te pellets me te 50% te siloxane polymer taumaha-ira tino teitei i whakamararatia ki roto i te polystyrene pānga-teitei (HIPS). He whānuitia te whakamahinga hei tāpiri tukatuka whai hua i roto i te pūnaha kapia hototahi PS hei whakapai ake i ngā āhuatanga tukatuka me te whakarerekē i te kounga o te mata.

Ki te whakataurite ki ngā tāpiringa Silicone/Siloxane taumaha-ngota iti iho, pērā i te hinu Silicone, ngā wai silicone me ētahi atu momo tāpiringa tukatuka, e tumanakohia ana ka pai ake ngā painga o te raupapa SILIKE Silicone Masterbatch LYSI, hei tauira, he iti ake te paheke o te tīwiri, he pai ake te tukunga pokepokea ai, he whakaiti i te turuturu o te mate, he iti ake te tauwehenga o te waku, he iti ake ngā raruraru peita me te tā, ā, he whānui ake ngā āheinga mahi.

Ngā Tawhā Taketake

| Tau | LYSI-410 |

| Āhua | Pēreti mā |

| % o te ihirangi silicone | 50 |

| Pūtake kapia | NGĀ HŪPA |

| Taupū rewa (230℃, 2.16KG) g/10min | 13.0 (uara noa) |

| Inenga% (w/w) | 0.5~5 |

Ngā Painga

(1) Whakapai ake i ngā āhuatanga tukatuka tae atu ki te kaha rere pai ake, te whakaiti i te paru o te mate extrusion, te iti o te taipana extruder, te pai ake o te whakakī me te tukunga o te pokepokea ai

(2) Whakapai ake i te kounga o te mata pērā i te paheke o te mata, te whakaiti i te Tauwehenga o te waku

(3) He ātete nui ake ki te pakū me te karawarawa

(4) Te tere ake o te tuku, te whakaiti i te tere o te hapa o te hua.

(5) Whakapai ake i te pumau ki te whakataurite ki te āwhina tukatuka tuku iho, ki ngā hinu whakahinuhinu rānei

Ngā tono

(1) Ngā hu TPR/TR

(2) Ngā elastomer thermoplastic

(3) Ngā kirihou hangarau

(4) Ētahi atu pūnaha hototahi PS

Me pēhea te whakamahi

Ka taea te tukatuka i te raupapa SILIKE LYSI silicone masterbatch i te ara kotahi ki te kawe kapia i ahu mai ai. Ka taea te whakamahi i roto i te tukanga whakaranu rewa matarohia pēnei i te extruder tīwiri kotahi/rua, te whakakoi werohanga. E taunakihia ana kia whakaranua he ranunga ā-tinana me ngā pire polymer tauhou.

Te horopeta tūtohu

Ina tāpirihia ki te polyethylene, ki te thermoplastic rānei i te 0.2 ki te 1%, e tumanakohia ana ka pai ake te tukatuka me te rere o te kapia, tae atu ki te pai ake o te whakakī pokepokea ai, te iti ake o te taipana extruder, ngā hinu whakahinuhinu o roto, te tukunga pokepokea ai me te tere ake o te whakaputanga; I te taumata tāpiri teitei ake, 2~5%, e tumanakohia ana ka pai ake ngā āhuatanga o te mata, tae atu ki te whakahinuhinu, te paheke, te iti ake o te tauwehenga o te waku me te nui ake o te ātete ki te mar/waru me te pakū.

Mōkihi

25Kg / putea, putea pepa mahi toi

Rokiroki

Kawehia hei matū kore-morearea. Penapena ki te wāhi hauhautanga, hauhautanga hoki.

Te roa o te oranga

Ka noho pūmau ngā āhuatanga taketake mō ngā marama 24 mai i te rā i hangaia ai, mēnā ka rongoatia ki te wāhi rokiroki e taunakitia ana.

Ko Chengdu Silike Technology Co., Ltd he kaihanga me te kaiwhakarato rauemi silicone, kua whakatapua ki te R&D o te whakakotahitanga o te Silicone me ngā thermoplastics mō te 20 tau.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnOne is increasing the melt temperature of HIPS can help to improve the surface quality of the material. This is because higher temperatures can help to reduce the viscosity of the material, which can help to reduce the number of surface defects. In addition, SILIKE silicone masterbatch can improve the surface quality of HIPS.

NGĀ TĀPIRI HAIRONA KOREUTU ME NGĀ TAUIRA Si-TPV NEKE ATU I TE 100 NGĀ TAURANGA

Momo tauira

$0

- 50+

ngā kōeke Silicone Masterbatch

- 10+

ngā momo Paura Silicone

- 10+

ngā kōeke Masterbatch Ārai-rakuraku

- 10+

ngā kōeke Masterbatch Anti-abrasion

- 10+

ngā māka Si-TPV

- 8+

ngā momo ware piro

-

Waea

-

Ī-mēra

-

Whatsapp

Whatsapp

-

Runga

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur